Nature, refined

Citribel is the only genuinely circular producer of citric acid, citrates, and other high-value co-products through natural surface fermentation of sugar molasses.

Essentially circular

Sugar molasses, the sidestreams from sugar refineries, make up the primary raw material for our unique natural production process. The molasses serve as the breeding ground for our Citribel fungus. The fungus creates citric acid and mycelium in the fermentation process. Citrates and other components are produced during further downstream processing. We recycle and upcycle our resources in a myriad of ways, generating a multitude of high-quality circular components

Read more about our processes here.

Expertly crafted

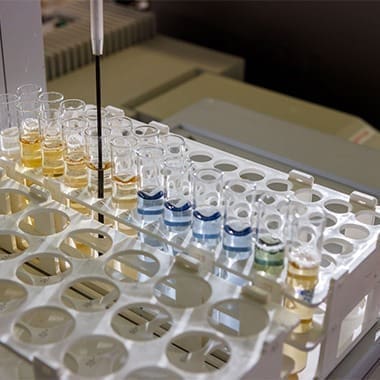

There’s more to our products than meets the eye. As a result of our proprietary fermentation and refinery processes, we achieve products with distinctive crystallographic and physicochemical properties. It is hard to overstate the amount of expertise, dedication, and organization it takes to finetune this living ecosystem of interconnected processes and streams.

Custom(er)-made

Not only are we constantly improving our processes and products, breakthrough applications for our citric acid, citrates, and other co-products surface day by day. We handle every question or request thoroughly, swiftly, and with a smile. The customer service team, the product management and sales team are at your service, from the first meeting to delivery and after-care.